HOME > Business > Cooperative development technology

BUSINESS DESCRIPTIONBUSINESS DESCRIPTION

Infinite possibilities for manufacturing

Cooperative developmentNew technology development

Streamline their operations in collaboration

We work with other companies in a variety of industry sectors with the aim of catering to the needs of customers for their product developments.

CUSTOMERcustomer

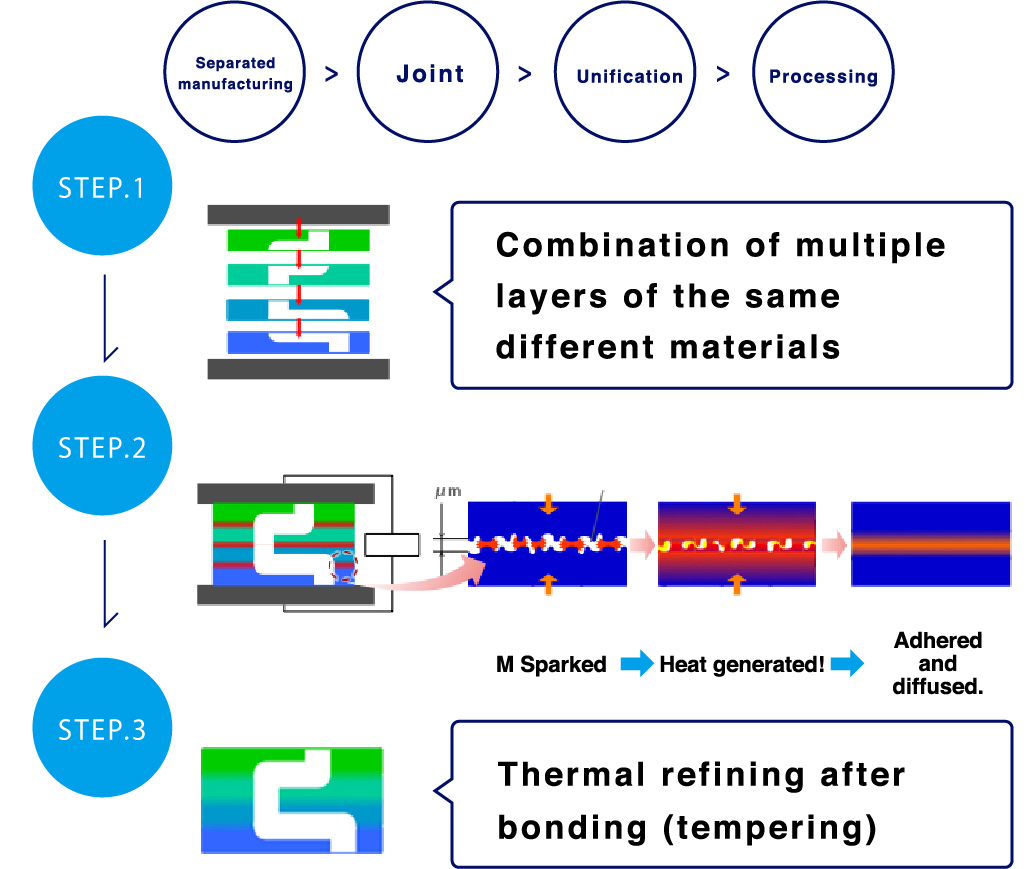

Special joining method

Use of direct joint

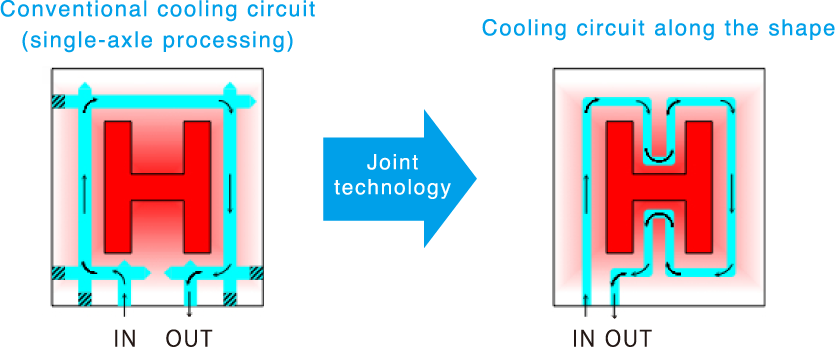

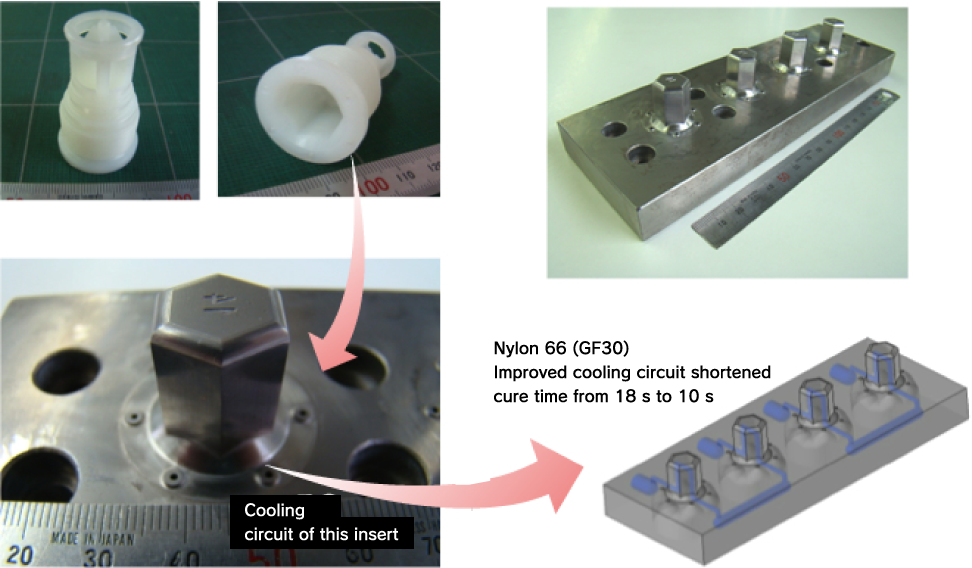

What can be achieved by molds?

Cases used for molds

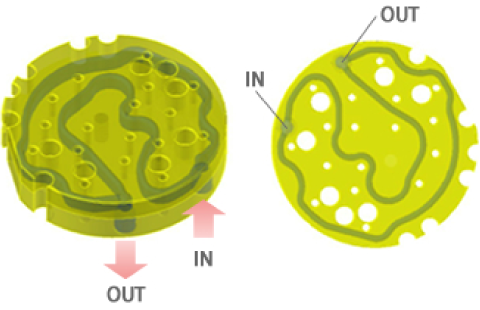

Humidity control plate

Applicable to such shapes that cannot be sealed with conventional packing and gasket.

Durability and reliability are much higher than seal structure.

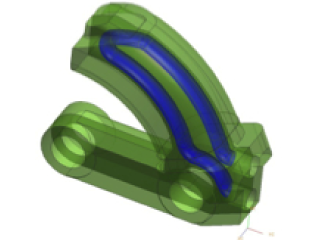

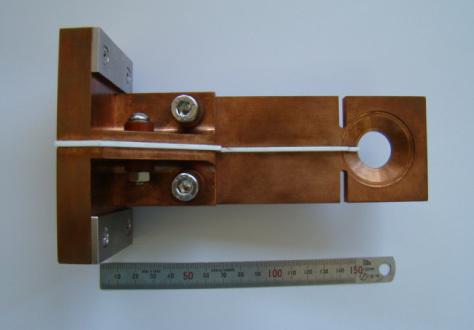

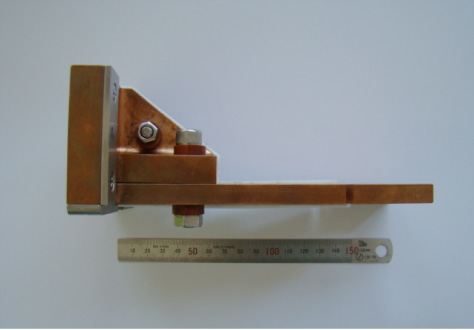

High-frequency heating coil

Technical overview

- 1.Use of direct joint can eliminate siilver brazing, realizing longer service life of high-frequency coils.

- 2.Proposal for reduction in coil replacement costs by changing the design concept from unified structure to separated structure.

Conventional structure

- Features

- Structures that have remained unchanged for nearly half a century.

Use of flat plates and pipes on an as-needed basis can minimize material costs. - Problem

- Service life depends on the technique of silver brazing which can be achieved by skilled craftsmen. Difficult to communicate with them from the procurement side, as they always handle high workload.

Difficulty in finding successors may arise, affecting productivity.

Handmade items require condition adjustment when replaced.

Proposed structure

- Features

- Structure consists of “dedicated part” and “general part” It only requires replacement of “dedicated part” at the end of service life, realizing low cost and a small footprint for storage.

- Problem

- Joint method is used.

Fixed and longer service life achieved because it is not brazed. High manufacturing accuracy requires no condition adjustment. Shorter delivery time with only the production of dedicated part.

Problem

Waste of material (padding) is inevitable because of its design.

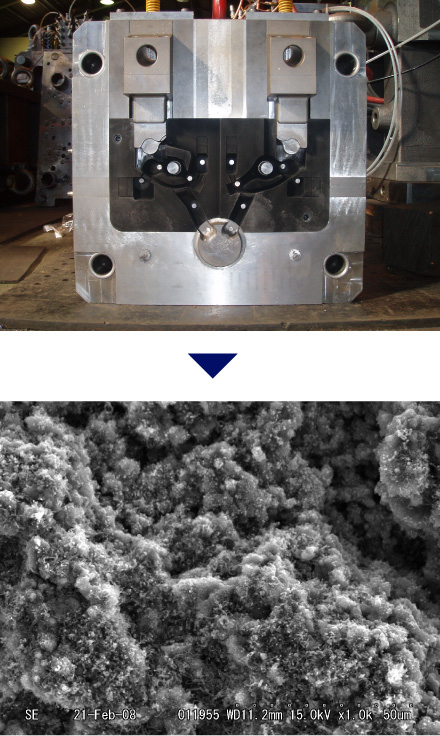

Mold surface treatment

Technical overview

Carbon coding

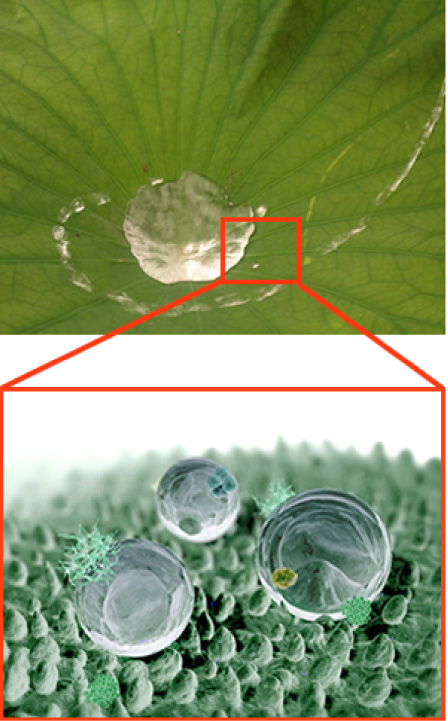

Lotus leaf

Metal surface turns into a state like a lotus leaf by the formation of carbon nanotube.

Technical performance and benefits

- Moisturizing type surface treatmentImproved fluidity

- Carbon filmPrevention of seizing

This patented technology for metal surface treatment enables us to form carbon nanotube on a metal surface.

The metal surface becomes like that of a lotus leaf and its, fluidity will be improved by the lotus effect.

In addition, the effect of carbon film prevents metal molds from seizing.

Strategic Core Technology Advancement Program(Supportin)

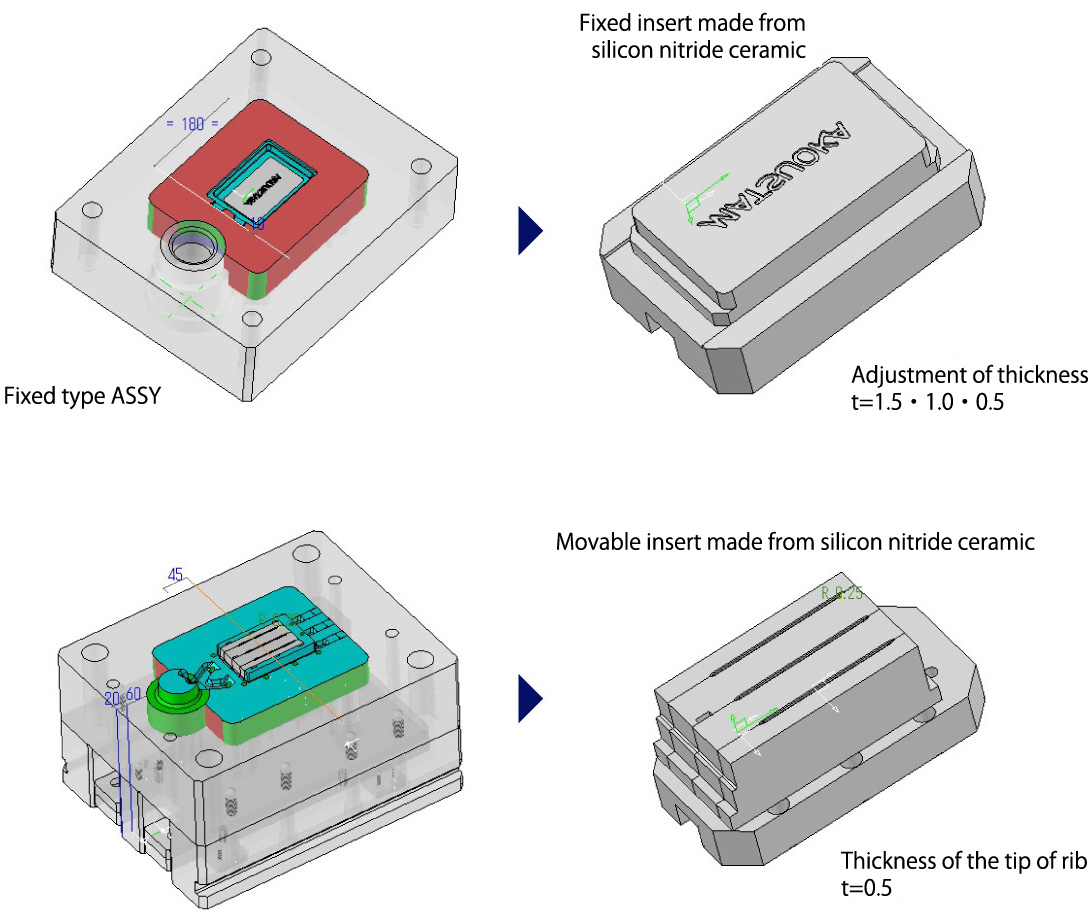

Technical overview

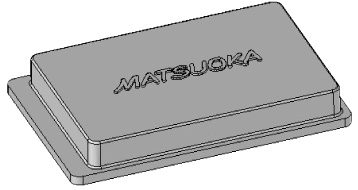

Forging sample

Aluminum die-casting

- Ceramic development to reduce the use of rare earth and specialty steel

- Boron carbide Silicon nitrideDevelopment of ceramic application

-

Boron carbide - ・・・・Alternate material of super hard mold

- ・・・・Alternate material of specialty steel

-

- Not react with aluminumBurn-in prevention

- No wettability with aluminumLiquidity improvement(TotalC/D)

Detailed design of mold

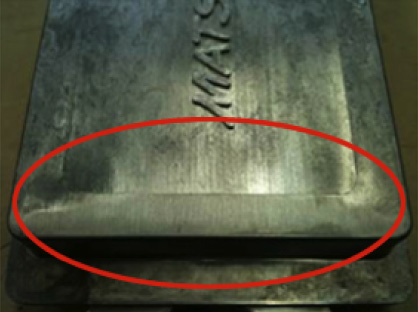

Appearance of casting product “Casting surface”・・・Difference in fluidity

Nitrogen Silicon Nitrate

Steel nest

Luster is different on the casting surface between silicon

nitride ceramic insert and steel insert.

Better fluidity of molten metal achieved by the silicon nitride ceramic.

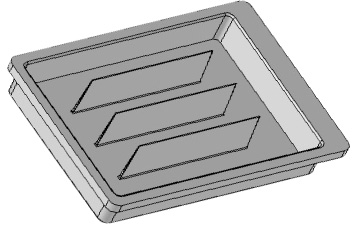

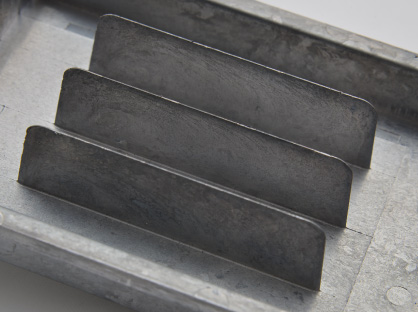

Appearance of casting “thin-walled rib”・・・Difference in fluidity

Nitrogen Silicon Nitrate

Steel nest

Filled state of rib at thickness of 0.5 mm is significantly different between silicon nitride ceramic insert and steel insert.

Contactお問い合わせ

For inquiries about products and services, please contact us using the inquiry form.

Click here for inquiries, quotations and consultations.

NAGOYA052-621-2136

GUNMA0276-73-2563